Heating cable introduction

Self regulating heating cable provide the most versatility in heat trace design and applications. Constructed of a Semi-conductive heater matrix extruded between parallel buswires, a self regulating cable adjusts its output to independently respond to ambient temperatures all along its length. As temperatures increase,the heater’s resistance increase which lower the output wattage. Conversely, as the temperature decrease, the resistance decreases and the cable produces more heat. So it is no need thermostat in some applications. It will never overheat or burnout even when wrapped by itself(overlapped). It can be cut to any length. So it is a convenient ,easy use and energy saving product.

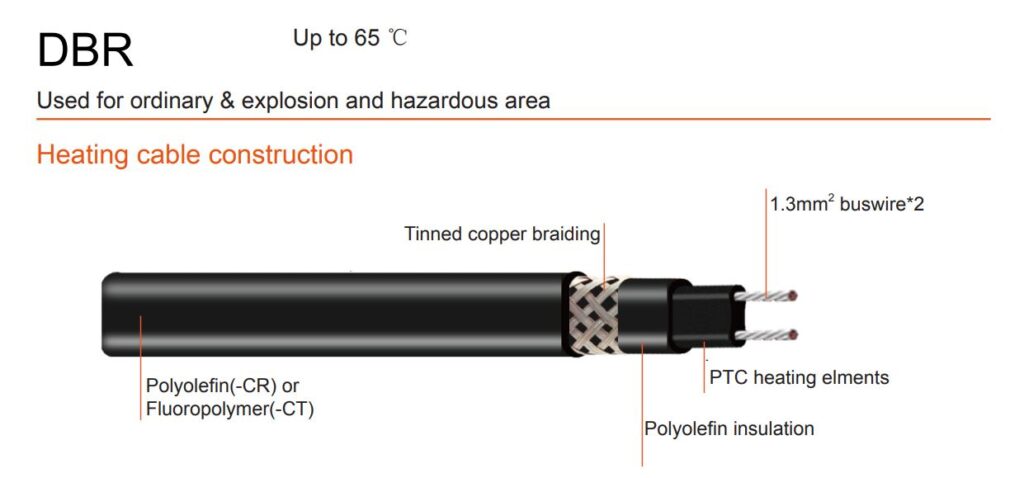

Heating cable construction data

-

CSI-DBR is a low temperature self regulating heating cable for pipes ,tanks and vessels, which can be used for freeze protection or temperature maintenance in industrial fields.

-

CSI-DBR also can be used for deicing heat tracing cable, self regulating gutter heat cable and self regulating roof heat cable in residential field.

-

It is normally suited to small diameter metal / non-metal pipes and roof & gutter tracing heat.

-

It can be cut-to-length at site.

-

DBR is approved for use in non-hazardous and hazardous areas.

-

Its self regulating heating element (PTC: Positive Temperature Coefficient) improves safety and reliability.

-

CSIDBR will not overheat or burnout, even when wrapped by itself.

-

Its power output is self regulated in response to the pipe & ambient temperature.

-

DBR can be manufactured by custom color and size.

-

Please use approved termination, splicing and power connection components with DBR heat trace cable.